| LBC Nylon | Material | LBC HDPE |

|---|---|---|

| Spun Cast Nylon | Manufacturing Method | Extruded HDPE |

| ISO 9000 | ISO Certification | ISO 9000 |

| Tests conducted in accordance with SANS 1313-3:2012, "Conveyor Belt Idlers, Part 3: Performance specifications for belt conveyor idlers." |

SA Manufacturing Compliance | Tests conducted in accordance with SANS 1313-3:2012, "Conveyor Belt Idlers, Part 3: Performance specifications for belt conveyor idlers." |

| Lorbrand | Manufacturer | Lorbrand |

| Composite Nylon | Shell Construction | Composite HDPE |

| Glass Reinforced Nylon | B/Housing Construction | Reinforced HDPE |

| 2500mm | Single Longest Roll Length | 2500mm |

| Poor | Sulphuric Aid Resistance | Excellent |

| 127, 152, 178 or to customer specification |

Std Diameters (mm) | 127, 152, 178 or to customer specification |

| Up to 60% less | Weight Reduction over Steel Rolls | Up to 60% less |

| 10, 15, 20 or to specification | Std Wall Thickness (mm) | 10, 15, 20 or to specification |

| 25 through 65 | Shaft Diameter (mm) | 25 through 65 |

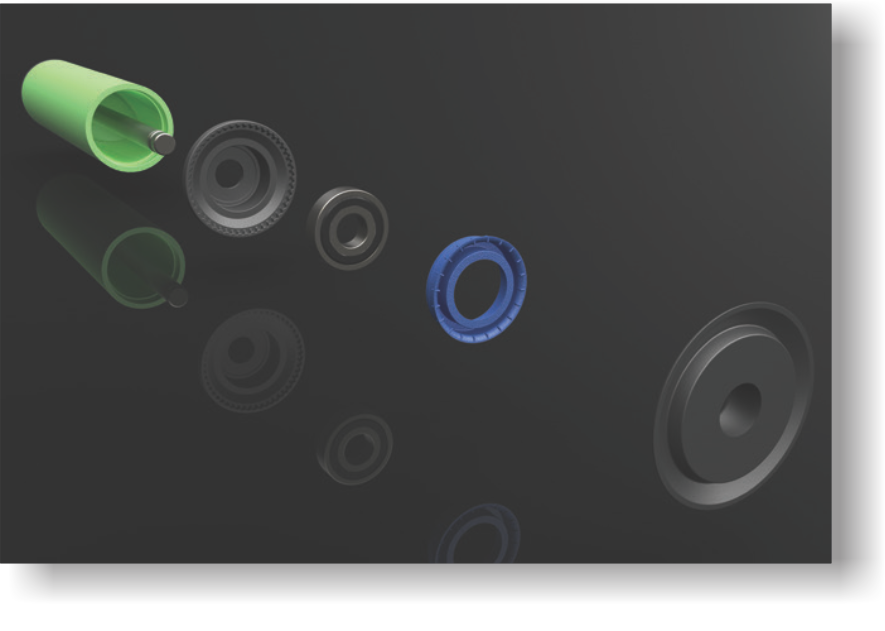

| 6205, 6305, 6306, 6308, 6309, 6310 |

Bearing Sizes | 6205, 6305, 6306, 6308, 6309, 6310 |

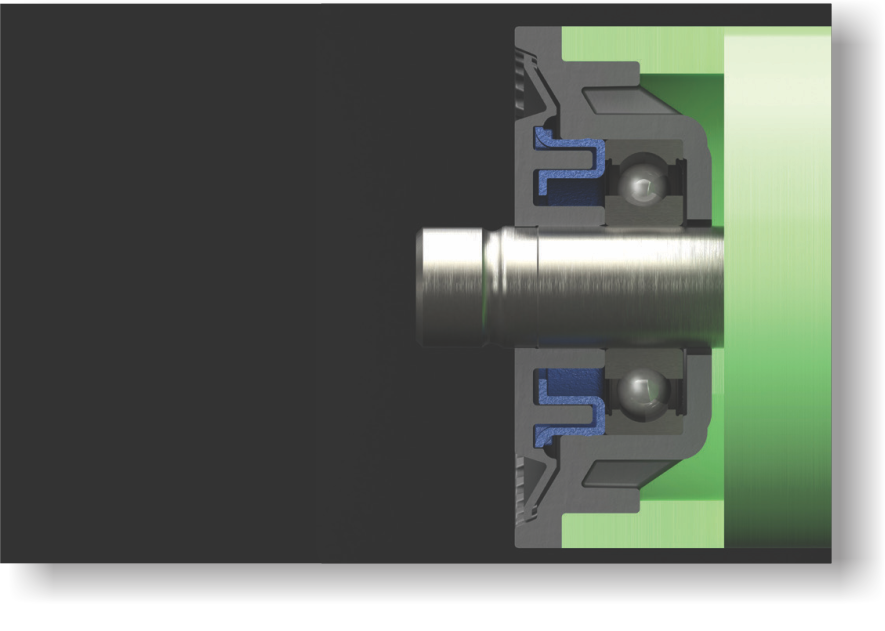

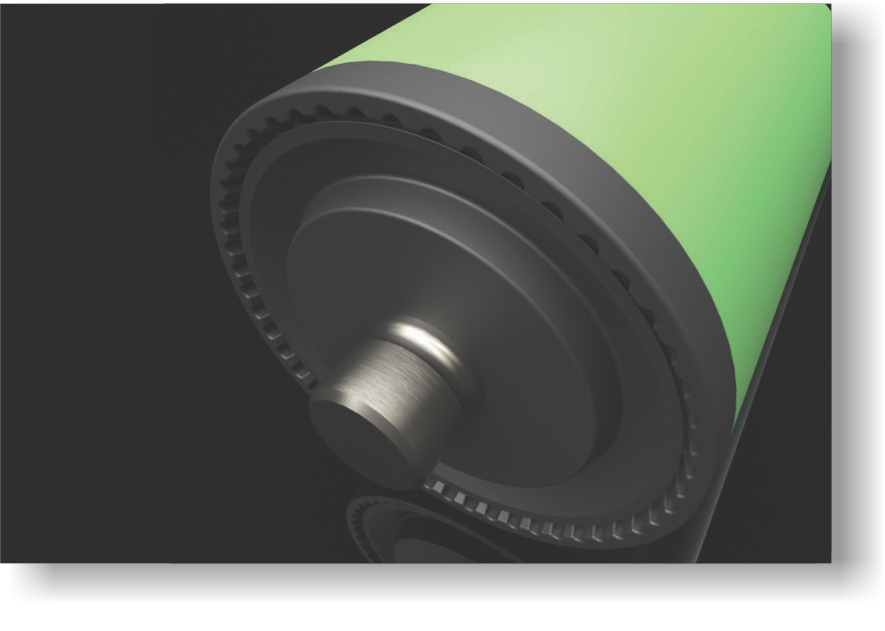

| Greased for life ball bearing | Bearing Type | Greased for life ball bearing |

| URB/LFD or customer specification |

Bearing Manufacturer | URB/LFD or customer specification |

| Non Contact Centrifugal Steal | Seal Type | Non Contact Centrifugal Steal |

| AS/NZS Standard | Fire Resistance | Not Applicable |

| AS/NZS Standard | Anti-Static | Not Applicable |

| Problem/Issue | Result | Solution |

|---|---|---|

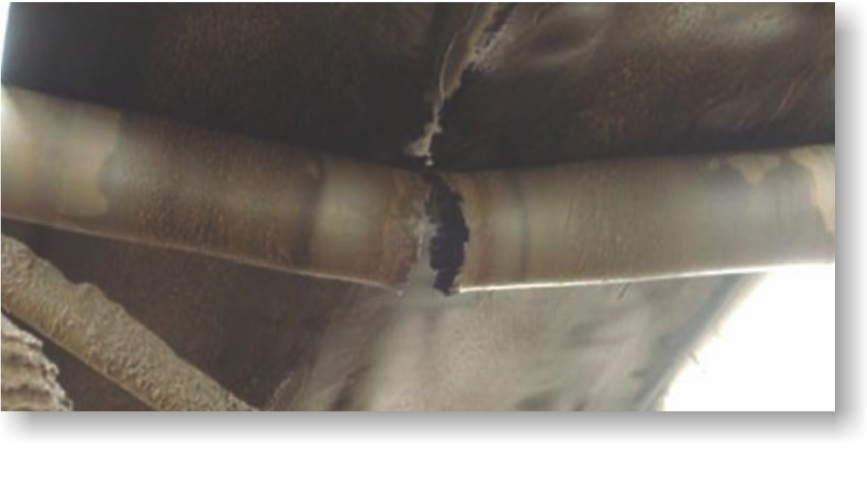

| Corrosion | Exposed steel continually oxidizes. Rust on rolls causes premature failure resulting in costly downtime and under utilized components. | Composite materials designed specifically to cope with corrosive environments. |

| Abrasion | Abrasive materials along with corrosive action causes premature wear and failure of the shell. | Composite material range designed to offer superior abrasion resistance to steel and other composite materials. (Sand/Slurry Tests) |

| Weight | Increased on site work injuries, high workers compensation claims. Increased fatigue as a result in carrying heavy steel rolls. Increased cost of spares due to poor maintenance, belt downtime. | Up to 60% weight reduction over comparable steel rollers. Ability to safely carry multiple rolls. No specific equipment required for larger roll installations. |

| Performance | Poor quality rolls fail prematurely causing costly roll replacements, as well as costly production downtime for maintenance purposes. | Quality roll and component design ensures optimal performance on the conveyor. |

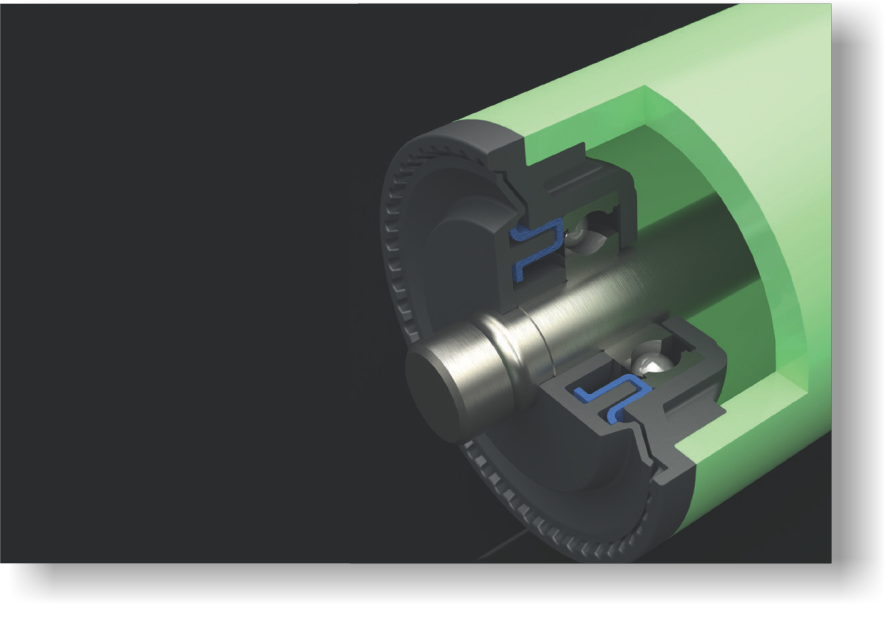

| Safety | Work related injuries as a result of heavy lifting and more time on the conveyor. | Composite materials make overall weight of roll considerably lighter. Hollow shaft technology can further reduce overall weight of roll. Large diameter stationary rock shield offers barrier to spillage that will abrade outer bearing housing. |

| Sealing | Premature roll failure due to ingress of moisture and dust into the bearing. | Sealing arrangements to suit your specific application (moisture/dust). Industry leading seal designs. Independently tested. |

| Increased Power Requirements | Design requirements increase to handle roll performance design specifications. (Breakaway mass and Seal Drag) Costs associated with operating a conveyor dramatically increase. | Low breakaway mass and running friction numbers maintained without sacrificing seal/roll performance. Power required to drive system can be reduced by up to 30% per system. Immediate cost savings. |

| Non Fire Resistance Compliance | Many composite rollers are not Fire Resistant, meaning underground applications cannot take advantage of the benefits associated with composite rolls. | FRAS roller meets Australian standards for Anti-Static and Flame Retardancy use in Underground Mines. |

| Non Anti-Static Compliance | Other composite rolls are unsuitable for underground use and sparking applications. | FRAS roller meets Australian standards for Anti-Static and Flame Retardancy use in Underground Mines. |

| Noise Pollution | Costly citations due to elevated noise emmissions. Failing componentry sound emissions not audible during inspections. | Rolls on average +-10dB lower than steel rolls. Implies up to 90% quieter than steel. Lower noise emmissions allow for improved problem identification. |

| Toxicity Levels | Fatal results due to inhalation of toxic fumes. Particularly relevant to confined working areas. | Rolls designed using non toxic composite materials. Independent testing data available. |

| Chemical Resistance | Premature roll failure due to chemical attack to the composite material. | LBC's range of proprietary materials allows for rolls to be used in very specific applications, such as sulphuric acid applications (HDPE) |

| Design Flaws | Composite rolls dimensionally incapable of certain size, length and load operating capabilities. Inconsistency with scale quality rolls (Steel/Other composites) | Proprietary materials offer no design restrictions for length and load requirements. No sections welded together. Standard roll is manufactured to scale roll specifications. |

Lorbrand Composites

| Shaft Diameters(Std)(mm) | Shell Diameters(Std)(mm) | Roll Face Length(mm) | Roll Material | Position | Bearing Size |

|---|---|---|---|---|---|

| 25 | 104 | Up to 2500 | N = Nylon | T = Trough | 6205 |

| 30 | 114 | F = Fras Nylon | R = Return Flat | 6305 | |

| 40 | 127 | Actual dependant on customer dimension | EN = Eco Roll | V = V -Return | 6306 |

| 45 | 452 | H = HDPE | 6308 | ||

| 50 | 178 | 6309 | |||

| 65 | 196 | 6310 | |||

| Non Standards Available on Request | Non Standards Available on Request | Capabilities (Single roll) | Customer Spec on Request |

Step 1: Provide Basic Roll Information (Additional Information Required for Roll Design Verification)

Additional information allows for load and design calculation verification

Step 2: Roll Part Number Generation

| LBC | - | 25 | - | 127 | - | 191 | - | NT | - | 6305 |

|---|

| Example | |

|---|---|

| Roll Shaft Diameter | 25 |

| Roll Shell Diameter | 127 |

| Roll Face Length | 191 |

| Roll Material Construction | N |

| Roll Position Location | T |

| Bearing Size | 6305 |

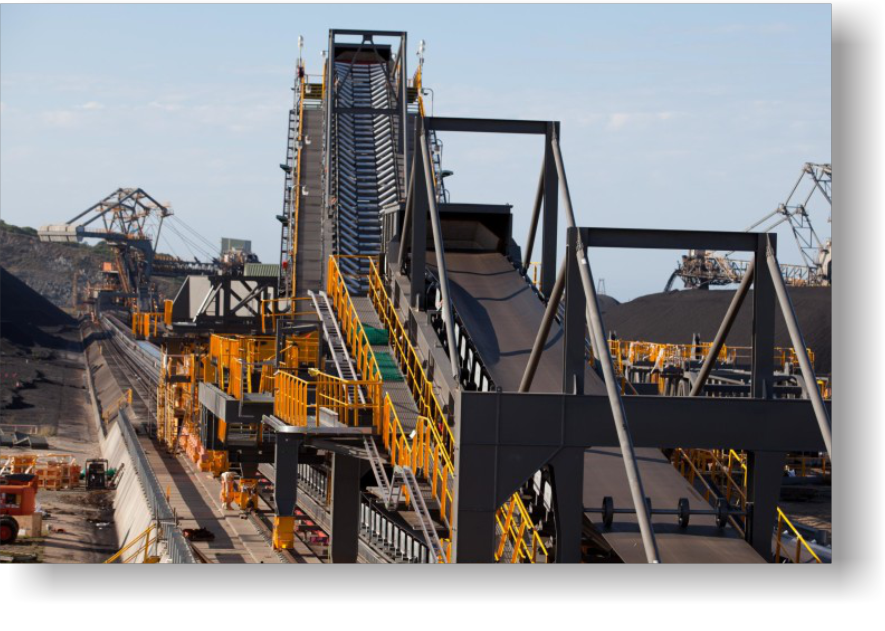

| Material Conveyed | Coal |

| Belt Speed (m/s) | 2.5 |

| Tonnes Per Hour Carried (tph) | 150 |

| Idler Spacing | 1.5 |